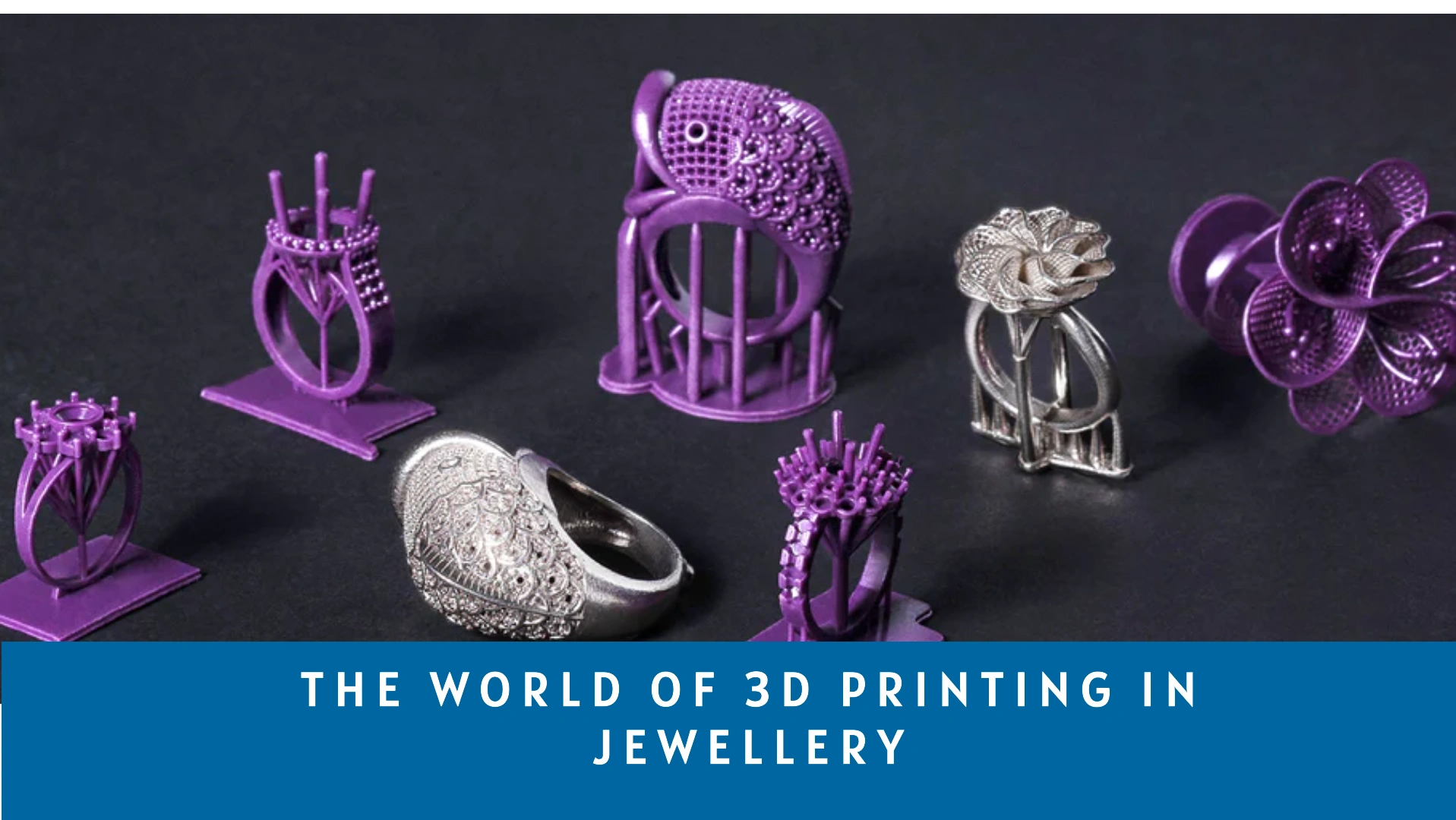

Welcome to the amazing world of 3D printing

in jewelry! Technology has changed the way beautiful jewelry is made. 3D

printing lets designers create incredibly detailed and unique pieces in a whole

new way. It's a mix of old-fashioned skill and new technology, allowing

designers to make custom designs and be more eco-friendly. The blog discusses

the impact of 3D printing on the jewelry industry, highlighting its influence

on design, customization, materials, sustainability, and more. Let's find out

how 3D printing is changing jewelry-making and why it's exciting for everyone

involved.

What

makes 3D printing unique in jewelry?

3D printing revolutionizes the jewelry-making

process in several unique ways, making it stand out from traditional methods:

1.

Customization:

It allows for a high level of customization,

enabling designers to create complicated, unique designs that were previously

difficult or impossible to achieve through traditional methods. This opens up a

world of possibilities for personalized and one-of-a-kind pieces.

2.

Complex geometries:

The technology enables the creation of

jewelry with highly complex geometries and intricate details that would be

extremely challenging or even impossible to produce using traditional

techniques. This offers designers the ability to push the boundaries of

creativity and craftsmanship.

3.

Reduced material waste:

Unlike traditional jewelry-making processes

that often result in significant material wastage, 3D printing can be more

resource-efficient, as it allows for precise material usage, reducing waste and

supporting sustainability efforts in the industry.

4.

Faster prototyping:

3D printing streamlines the prototyping

process, allowing designers to quickly iterate and test new designs without the

need for extensive manual labor, thus accelerating the product development

cycle.

5.

Accessible production:

With 3D printing, jewelry-making becomes more

accessible to a broader range of designers and artisans, as the technology

reduces the barriers to entry, particularly for those looking to create

small-batch or custom pieces.

Unleashing

Creative Freedom:

3D printing gives jewelry designers more

freedom to be creative. Unlike traditional methods with certain limitations, it

allows designers to imagine and create more complex shapes and intricate

details. With the help of computer software, designers can easily bring their

ideas to reality. This technology empowers them to go beyond the usual and

create jewelry designs that were previously impossible to make using traditional

methods.

Customization

and Personalization:

With 3D printing, jewelry can be customized

to match each person's style. This means customers can get involved in the

design process and ask for exactly what they want, like the size, shape, and

placement of gemstones. They can even add personal touches to make the piece

truly unique. This way, every jewelry item becomes one-of-a-kind, making it

extra special for the person wearing it.

Can

customers provide design specifics?

Yes, customers can actively participate in

the design process regarding 3D-printed jewelry. They have the opportunity to

provide specific design requirements such as size, shape, gemstone placement,

and material preferences, and even incorporate personal elements into their

custom piece. This level of customer involvement ensures that each jewelry item

is tailored to their unique preferences, making it truly one-of-a-kind and

meaningful to the wearer.

Can

they choose materials?

Yes, customers can indeed choose the material

for their 3D-printed jewelry. With a wide range of materials available for 3D

printing, such as various metals, resins, and even specialty materials like

precious metals, customers have the flexibility to select the material that

best suits their preferences and requirements. This freedom to choose the

material adds another layer of personalization to the jewelry, allowing

customers to create pieces that are not only visually stunning but also align

with their preferences for durability, aesthetics, and value.

Rapid

Prototyping and Iterative Design:

Making jewelry samples used

to be slow and expensive. Now, 3D printing lets designers create quick and

exact models. This helps them see how the jewelry looks, make changes, and get

it perfect before making a bunch. It saves time, money, and ends with happier

customers!

How

does 3d printing in jewelry production contribute to customer satisfaction?

3D printing in jewelry production contributes

to customer satisfaction in several significant ways:

1.

Customization and Personalization:

It enables customers to actively participate

in the design process, allowing them to provide specific design requirements

and incorporate personal elements into their jewelry pieces. This level of

customization ensures that each piece is tailored to the individual's unique

preferences, leading to higher customer satisfaction through personalized

jewelry.

2. Design Flexibility:

With this technology, jewelry designers can

create intricate and unique designs that were once unattainable through

traditional methods. The ability to produce a diverse range of designs that

cater to different tastes and styles increases customer satisfaction by

offering a wider selection of options to choose from.

3. Quality Assurance:

The iterative design process facilitated by

it ensures that jewelry pieces undergo thorough refinement and testing before

production, resulting in high-quality, well-crafted items that meet or exceed

customer expectations. This commitment to quality contributes to customer

satisfaction and trust in the brand.

4. Visual Representation:

Through this technology, designers can create

precise physical prototypes that provide customers with a realistic

representation of the final jewelry piece. This visual representation helps

customers make more informed purchasing decisions and fosters confidence in the

product they are ordering.

5. Reduced Lead Times:

The rapid prototyping capabilities shorten

the design and production timeline, allowing customers to receive their

customized or personalized jewelry in a more timely manner. This efficiency

contributes to customer satisfaction by delivering products within shorter lead

times.

Material

Variety and Innovation:

3D printing provides a wide range of

materials for making jewelry. In jewelry production, a wide variety of

materials can be utilized to create unique and innovative pieces. Some of the

common types of materials used include:

1.

Precious Metals:

- Gold

- Silver

- Platinum

2.

Non-Precious Metals:

- Brass

- Bronze

3.

Resin:

Resin materials offer a range of colors and

finishes, suitable for intricate designs and detailed pieces.

4.

Ceramics:

Ceramic materials provide a unique look and

feel, allowing for the creation of delicate and refined jewelry pieces.

5.

Composite Materials:

Composite materials combine elements to

achieve specific properties, enabling designers to experiment with textures and

structures.

6.

Specialty Metals:

Materials like titanium or stainless steel

can also be used to create modern and durable jewelry pieces.

Sustainable

and Environmentally Friendly:

Jewelry-making can be

wasteful! Lots of leftover materials get thrown away. But 3D printing is like a

special kind of printer that builds jewelry piece by tiny piece, wasting less

material. This cool tech helps make pretty jewelry in a way that's better for

the environment!

Can

you explain layer by layer?

Layer-by-layer is a fundamental concept in 3D

printing that refers to the systematic process of building an object one thin

layer at a time. Here's a detailed explanation of how layer-by-layer printing

works in 3D printing:

1.

Digital Design:

The process begins with a digital 3D model of

the object that needs to be printed. This design serves as a blueprint for the

printer to follow during the printing process.

2.

Slicing:

The 3D model is sliced into numerous

horizontal layers by specialized software. Each layer is like a slice showing a

different part of the finished object.

3.

Printing Process:

The 3D printer begins by making the first

layer of the object right on the build platform. It does this by depositing or

curing the printing material (such as plastic, resin, or metal) in a specific

pattern based on the sliced design.

4.

Layer Bonding:

Once the initial layer is completed, the

printer moves on to the next layer, building on top of the previous one. The

material in each layer fuses or adheres to the layer below it, creating a

strong bond between the successive layers.

5.

Repetition:

The printer repeats the process of depositing

and solidifying material layer by layer, following the precise instructions

from the sliced design. This step-by-step process keeps going until the whole

object is finished.

6.

Complex Structures:

Layer-by-layer printing allows for the

creation of complex geometries and intricate designs that would be challenging

or impossible to achieve with traditional manufacturing methods. Each layer

contributes to the overall structure of the object, leading to the gradual formation

of the final three-dimensional shape.

Can

small jewelers afford 3D printers?

Yes, small jewelers can afford 3D printers

due to the decreasing costs and increasing accessibility of this technology.

Entry-level desktop 3D printers are now more affordable, making them within the

reach of small-scale businesses. Additionally, some companies offer leasing or

financing options, further easing the financial burden of acquiring a 3D

printer. The cost of 3D printers continues to decrease as the technology advances,

making it increasingly feasible for small jewelers to invest in this

transformative manufacturing tool.

Quality

and Artisanship:

3D printing lets designers

create amazing and custom jewelry, but it doesn't replace the skills of a

jeweler. Many use both techniques! They might 3D print a base, then hand-finish

it, set stones perfectly, and polish it for a dazzling final piece. This keeps

the best of both worlds: cool designs and top-notch craftsmanship.

In summary, the use of 3D printing in jewelry

has brought together innovation, accessibility, and traditional craftsmanship.

This technology has expanded design possibilities and made jewelry-making more

open to everyone. As 3D printing continues to inspire creativity and reshape

the jewelry industry, we see a bright future where modern technology and

timeless artistry come together. This marks an important moment in the

industry's history, where the past and the present join forces, offering

endless potential and creativity in the world of jewelry.